Customized Project

134MW TOPCon Project

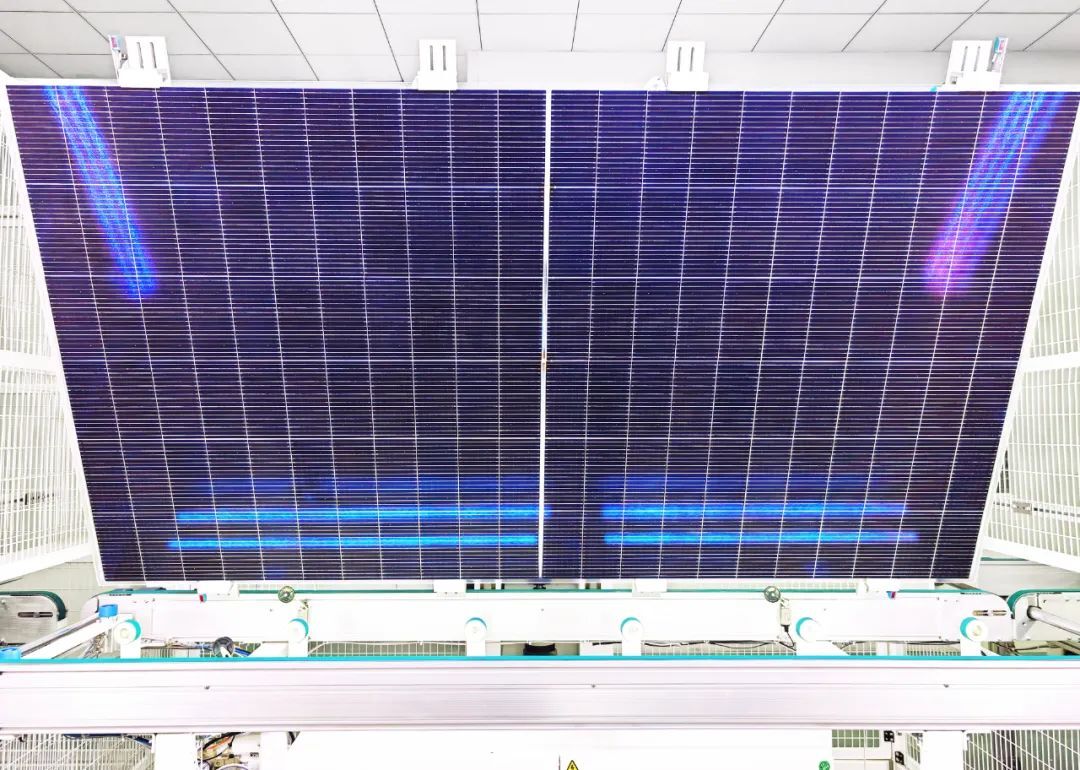

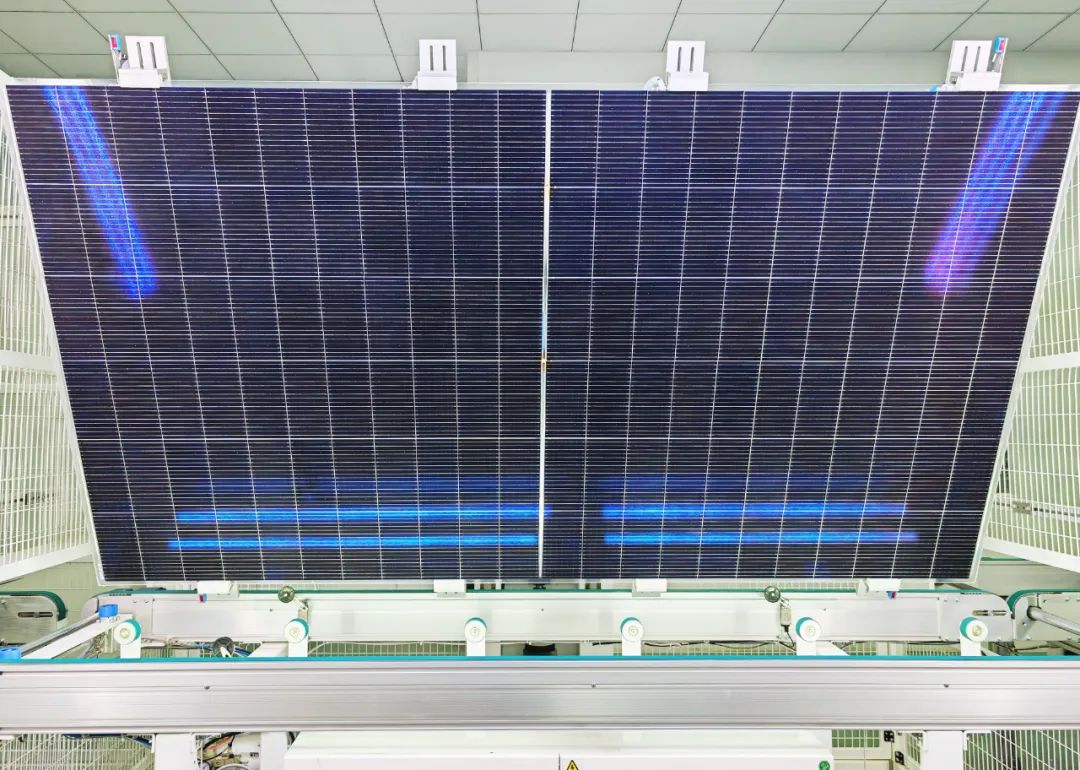

Recently, JinenU Solar has received a customized production order from a customer, which focuses on high-efficiency, large-size N-type PV modules - 210R-66 version. The core demand of this order is to customize two kinds of power modules, 605W and 610W, and the total amount of the order reaches 134MW, with a total of 221,168 pieces.

In order to realize efficient production, JinenU Solar has formulated a multi-dimensional production and delivery plan based on the customer's plate type and delivery date, and fully utilized the synergistic advantages of its two production bases in Tai'an and Taizhou, to ensure that it maintains a high yield and high rate of production in the large-scale production at the same time. Through the scientific and reasonable production plan arrangement, the production lines in the two places work closely together to maximize the utilization of resources, effectively shorten the production cycle, and lay a solid foundation for rapid response to customer needs.

Manufacturing Challenges & Solutions

The overall size of this N-type 210R-66 double-glass module is 2382*1134mm, and the cell size is 182*105mm. It uses 0.24mm specification round wire welding tape with EVA400+EPE420 grams+embossed double-coated glass, and the small 0.8mm pitch of the pieces can effectively reduce the grid line shading of the cells, improve the optics utilization, and increase the power of the module.

Due to the use of 0.24mm welding tape in this version, the bending of the welding tape occurs in the spacing of the battery strings of the string welding machine during the trial production, compared with other versions with longer dimensions, hidden cracks at the location of the center hole lead wire, broken pieces caused by the force of the welding tape vertical lamination, hidden cracks in the eight characters after the layer, etc., the manufacturing department of JinenU conducted comprehensive researches from the angle of material selection, design optimization to the adjustment of the lamination machine in the production process. After repeated tests and optimization, we not only successfully solved the current problems, but also provided valuable experience for the subsequent production, improved the production efficiency and product quality, and ensured the timely delivery of orders.

Customer Feedback

"From raw material inspection to finished product shipment, each process is strictly inspected to ensure that each module meets even our expectation standards. In terms of delivery time, JinenU's responsiveness is impressive, in the face of tight time requirements, they quickly mobilized their resources and ensured the steady progress of production through the highly efficient linkage of the two bases in Tai'an and Taizhou. " JinenU Solar always adheres to the values of integrity, goodness, refinement, and honesty, and produces every module with heart and soul.

MoreNews

-

2024-12-30

JinenU Solar's 7th Domestic Base To Be Located in Meishan(Sichuan Province) -

2024-12-30

JinenU Solar Tai’an Base 2-Year Anniversary Since Put Into Production -

2024-12-23

Qianshan Base Put Into Production For One Year -

2024-12-13

Media Focus | Wu Fei, Founder and Chairman of JinenU: Innovative Business Models to Realize Capacity Sharing -

2024-12-05

Tai'an Base GM Zhang Pengfei Attend the 18th China New Energy International Forum -

2024-12-02

Customized Project | JinenU 210N High-Efficiency, Large-Size 700W Module Project -

2024-11-20

Chairman Wu Fei: Focusing on OEM|ODM services & sharing production capacity -

2024-11-13

Customized Project | JinenU Solar 182-78N 630W Bifacial Module Project -

2024-11-11

Deputy Editor-in-chief of Qiushi (Seeking Truth) Magazine visited JinenU Solar Tai'an Base -

2024-11-01

Customized Project | JinenU Solar High-Efficiency, Large-Size 210R-66 Module Project -

2024-10-17

Customized Project | JinenU Solar 514MW 210N Topcon Project -

2024-10-12

JinenU Solar Zibo Production Base was honored as “Morning Star Factory” in Shandong Province -

2024-09-25

2-Year Anniversary of JinenU Solar Taizhou Base put into production -

2024-09-25

JinenU Solar Zibo Base was honored as one of the Top 100 Zibo Enterprise in Zibo City -

2024-09-09

Mr Wu Fei attended the Indonesia International Sustainability Forum 2024 (ISF) and Delivered Speech -

2024-09-06

JinenU Solar won "2024 Influential PV Intelligent Manufacturing Outstanding Employer Starlight Award" for the second consecutive year! -

2024-09-03

JinenU Solar Global Layout| Chairman Wu Fei attended the signing ceremony of PV supply chain cooperation in Indonesia -

2024-09-03

JinenU made its debut at The SmarterE South America 2024! -

2024-08-12

Customized Project | JinenU Solar 489MW 210-66 Topcon Project -

2024-07-25

Mr. Wu Fei: Focus on Mobilizing Demand and Optimizing the Ecosystem -

2024-07-25

Customized Project | JinenU Solar 134MW 210R-66 Module Project -

2024-07-01

JinenU Solar was selected as the director unit of All-China New Energy Chamber of Commerce -

2024-06-27

Intersolar Europe | JinenU Solar shines with its OEM|ODM Products and Services! -

2024-06-27

Mr. Wu Fei was invited to the 12th Global Green Energy and PV Finance Summit -

2024-06-27

20GW Focus on OEM! JinenU Solar Shines at Shanghai SNEC PV+ 2024 -

2024-06-03

The First TOPCon Module of the 3.6GW High-efficiency Module Project at Hexian Base Has Been Successfully Produced -

2024-06-03

The First TOPCon Module of the 3.6GW High-efficiency Module Project at Yuexi Base Has Been Successfully Produced -

2024-05-28

Customized Project | JinenU Solar 210-66N Large Size Module Project -

2024-05-16

Mr. Wu Fei, Chairman of JinenU Solar Group, Elected as Vice President of All-China New Energy Chamber of Commerce -

2024-05-16

Customized Project | JinenU Solar 1GW Large-Size Rectangular 182R, 210R Project -

2024-05-16

Customized Project | Trimming up to 39 times, JinenU Solar 200.6MW high-efficiency N-type and P-type module project -

2024-03-02

ODM|OEM mode shines in Tokyo! JinenU Solar makes appearance at PV EXPO 2024. -

2023-12-08

Customized Project | JinenU Solar Micro-rectangular 78.6MW High Efficiency Module Project -

2023-10-12

Customized Project|JinenU Solar 1.6MW All-Black TOPCon Module Customization Project

If You have ODM|OEM Requirement, Please Contact Us

Our professional team will provide the satisfactory customized production proposal for you