Customization File

514MW TOPCon Project

Recently, JinenU Solar received a customized production order from for N-type TOPCon high-efficiency, large-size 210-66 bifacial modules with power requirements of 700W, 705W, and 710W, with a total order volume of 514MW and a total of 734,000 pieces.

Manufacturing Challenges & Solutions

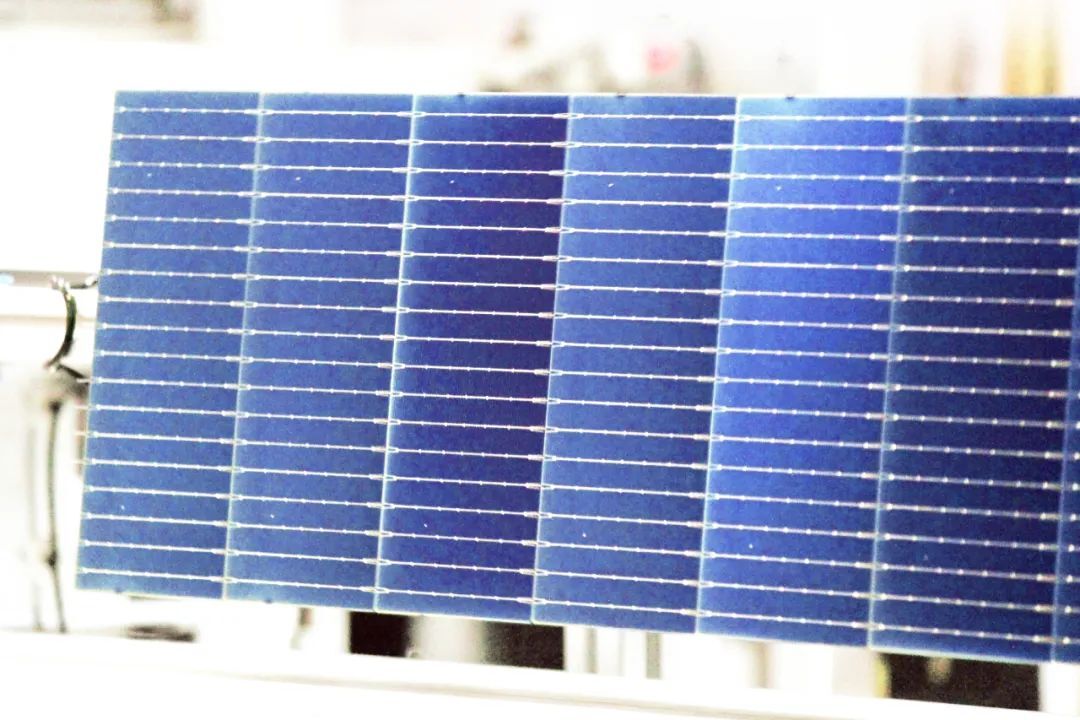

The 210-66N bifacial TOPCon module adopts 0.26mm round filament welding tape, combines 390g EPE and 420g EVA high-efficiency packaging materials and embossed double-coated glass. Through the design of 0.8mm small piece spacing and the application of multi-master grid technology, it effectively reduces the shading of the welding tape, and significantly improves the utilization rate of light and the efficiency of current collection, which greatly enhances the This significantly enhances the power output and overall reliability of the product.

In recent years, silicon wafers in the PV industry tend to be larger and thinner, accompanied by the reduction of the gram weight of the film, the phenomenon of broken wafers occurred in the production process. In response to this challenge, JinenU Solar Tai'an Base quickly responded by optimizing and upgrading the lamination process, and successfully overcame this technical problem by accurately regulating the lamination pressure and temperature parameters required by different cells, and achieved rapid improvement in production efficiency after 8 hours of close monitoring and improvement.

In addition, due to the large size of 210N type module cell, the overall size is 2384*1303*33mm, the welding tape needs to cross a longer distance when welding, which puts forward a very high demand on the precision and stability of the welding equipment, resulting in the emergence of the cell empty welding problem. In order to solve this problem, JinenU Solar Tai'an base has finely optimized the parameters of the welding machine and regularly maintained and calibrated the welding equipment, which has made the product quality of 210N-type customized modules jump to a new height.

Customer Feedback

"The professional service and quick response capability of the team at JinenU's Tai'an base, especially in the face of production challenges, the flexibility and efficient solution capability demonstrated by JinenU ensured the smooth and efficient production process, as well as the smooth execution of the large-scale order of 514MW, which has made us deeply trust JinenU's strength and integrity. "

JinenU Solar always adheres to the values of integrity, goodness, refinement, and honesty, and produces every module with heart and soul.

ODM|OEM生産リクエストがございましたら

お問い合わせください

我々専門チームよりお客様のニーズに応じてカスタム生産案を提案致します